The Role of Custom Hydraulic Cylinders in Various Industries

Have you ever wondered about the hidden mechanics that keep our industries running smoothly? One unsung hero is the custom hydraulic cylinder. This vital component, shaped by the process of hydraulic fabrication, plays a crucial role in the functioning of various industries across Australia and the world. Let's delve deeper into what these cylinders are and how they contribute to different sectors.

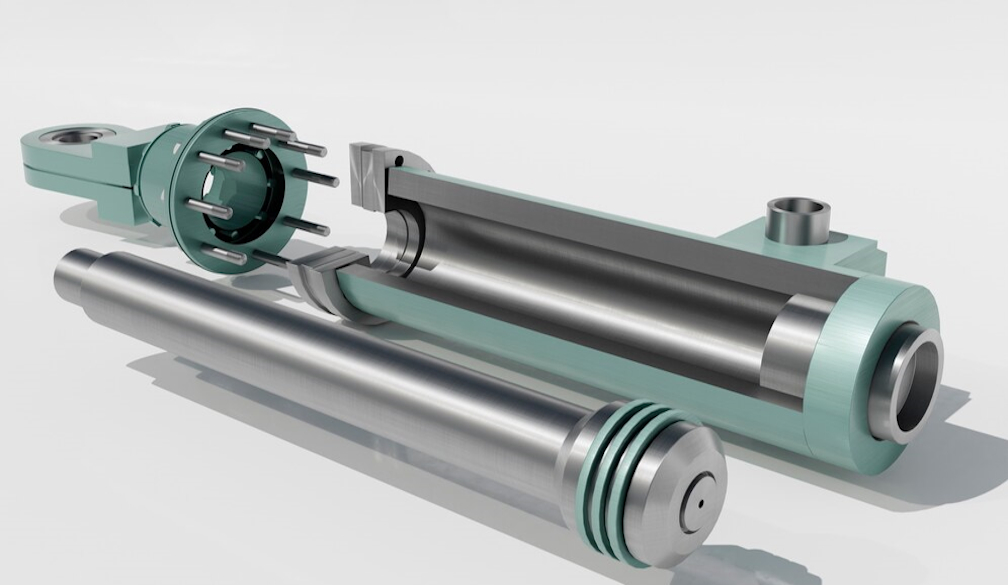

What are Custom Hydraulic Cylinders?

Custom hydraulic cylinders are mechanical devices used for creating a force in a straight line or linear motion. These cylinders are custom because they are designed and manufactured to meet specific requirements. Whether it's adjusting the size, material, or the pressure capacity, these cylinders can be tailored to suit the particular needs of an industry or project.

Different Industries That Use Hydraulic Cylinders

Manufacturing Industry

In the manufacturing sector, custom hydraulic cylinders are like the lifelines of production lines. They are used in machinery for tasks such as pressing, stamping, forging, and moulding. By offering high power output, precision, and flexibility, these cylinders help increase efficiency and reduce downtime on the factory floor.

Construction Industry

The construction industry is another arena where custom hydraulic cylinders show their mettle. They are integral to heavy machinery like excavators, bulldozers, and cranes. Whether it's lifting heavy loads or digging deep into the earth, these cylinders provide the necessary power and control, making construction tasks safer and more efficient.

Agriculture Industry

In the agriculture sector, custom hydraulic cylinders are used in equipment like tractors, harvesters, and ploughs. They help streamline various farming operations, from tilling the soil to harvesting crops, enabling farmers to work more efficiently and yield better results.

Mining Industry

Australia's mining industry, one of the most significant contributors to its economy, also relies heavily on custom hydraulic cylinders. They are used in drilling rigs, excavators, and dump trucks, playing a crucial role in extracting valuable resources from the earth. The ruggedness and durability of these custom cylinders make them perfect for the harsh conditions of mining operations.

Hydraulic Fabrication

Hydraulic fabrication is the process that brings these custom hydraulic cylinders to life. It involves designing, manufacturing, and assembling the cylinders to meet specific requirements. This process ensures the cylinders can withstand the demanding environments they operate in and perform their tasks with utmost efficiency.

Hydraulic fabrication allows for the creation of robust and durable cylinders that can resist wear and tear, thereby extending their lifespan. Moreover, it enables the production of cylinders that can handle high pressure, crucial for industries like mining and construction where heavy loads are common.

The exploration of custom hydraulic cylinders and their role across different sectors reveals their undeniable importance. The process of hydraulic fabrication not only brings these cylinders to life but also ensures they can meet the unique demands of each industry. By providing power, precision, and durability, these customised cylinders help drive the success of various industries, from manufacturing and construction to agriculture and mining. So, the next time you see a bustling factory, a soaring crane, or a busy farm, remember the custom hydraulic cylinders working tirelessly behind the scenes. Their role may be hidden, but their impact is vast and far-reaching.